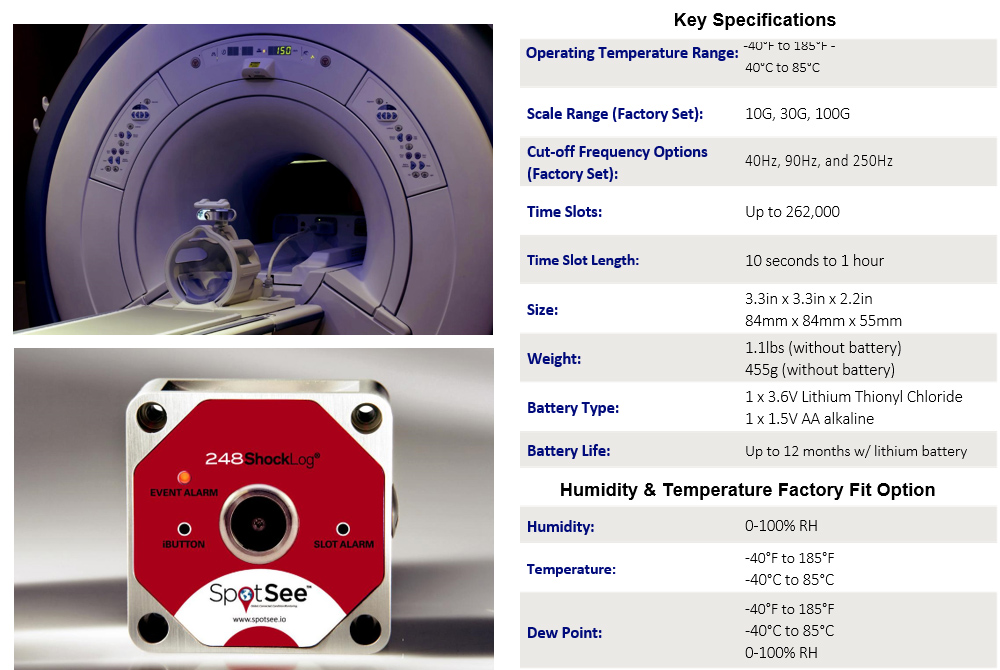

The ShockLog 248 is the entry model in the ShockLog product line of impact recorders, which includes the ShockLog 298 impact recorder. Available in 10G, 30G, and 100G impact scale ranges, the ShockLog 248 monitors impact and internal temperature, provides peak value (time slot) and summary period journey profile data. ShockLog 248 delivers a visual alert that your product has encountered impact events that might affect its performance or safety, enabling immediate inspection and remediation at the time shipment is received or before installation in the field. The ShockLog 248 will record the detailed impact curve for the first and 14 most significant events. Up to 128 event notifications are maintained in the event summary log.

Features

? Record max peak X, Y, and Z and internal temperature

? Record impact events for up to 15 events

? Field-proven triaxial piezoelectric accelerometer technology

? Show direction of impact—X, Y, and Z

? User-definable alarm levels

? Programmable wake-up levels for maximizing battery life

? LED lights for visual notification of alarms and warnings

? Self-contained unit design, free of cables and wires

? iButton? and USB data transfer options

? IP67-rated, RF-screened

? Temperature/humidity sensor built into unit (optional)

The ShockLog 248 is a highly durable impact recorder that can be configured to monitor critical parameters, providing an unmistakable alert that an impact to a shipment or equipment may have compromised its integrity, performance, or safe operation.

ShockLog 248 Applications

The ShockLog 248 is designed for a variety of applications where a single range/ frequency filter is required. This versatile impact sensing solution also offers optional environmental recording capability, monitoring your products in transit, in use, and in storage.

Below is a small sampling of applications in which the ShockLog 248 has been used:

? Automotive parts: motor, pumps, windshields, engines, transmissions

? Transportation: rail cars, barges, cranes, trucking fleets

? Energy: oil and gas drilling, power transformers, nuclear materials, solar panels, wind turbines

? Defense and aviation: lasers, missiles, munitions, gyroscopes, aircraft engines, rocket boosters, satellites

? Medical and research: lab equipment, particle accelerator systems, MRI machines, dental chairs

ShockLog? 248 Impact Monitor Overview

Data Transfer

The ShockLog has two options for data transfer: USB or iButton? interface.

Gain complete programming control and full data access over the USB port. iButtons allow for easy control for setup, download, and start and stop of the ShockLog. An overview can be downloaded using an iButton while keeping the unit secure and tamperproof.

ShockLog Software Allows for Configuration, Data Extraction, and Analysis

? Simple Windows?-based software program

? Clear instructions for quick deployment and easy data analysis

? Overview of the entire journey with peak acceleration values for all three axes reported on a time basis

? Export data into programs such as Excel for more detailed analysis

Protect Your High Value Assets

Customers use the ShockLog 248 impact recorder to:

? Alert recipients and operators to inspect goods and equipment for potential damage

? Detect mishandling during shipping, operation or storage, enabling you to identify and assign accountability and take corrective action

? Make adjustments to product packaging, loading process, carriers, or mode of transport

? Help identify opportunities for improvement through journey profiling